O loʻo oʻo mai se manaʻoga e sili atu ona manaʻomia mo le televave o fesoʻotaʻiga ma le gafatia tele ma le faʻateleina o le faʻaogaina o ao i le vaitau o faʻamatalaga tetele.40 / 100G fesoʻotaʻiga ua faʻatuputeleina faʻateleina i nofoaga autu o faʻamatalaga.I le avea ai o se isi mea i MPO cable, MTP® cables ma sili atu le faʻatinoga o le tulaga le maalofia i le faʻaogaina o faʻamatalaga nofoaga autu.MPO vs MTP®, o a mafuaʻaga e sili atu ai le mea mulimuli i le muamua?Aisea e tatau ai ona tatou filifilia le "manumalo" MTP® uaea e fai ma filifiliga muamua?

O a MPO ma MTP® Uaea?

O uaea MPO (Multi-Fiber Push On) o lo'o pupuni i so'o MPO i itu uma e lua.O le MPO connector o se feso'ota'iga mo uaea lipine e le itiiti ifo i le 8 alava, lea ua mamanuina e tu'uina atu ai le tele-fiber feso'ota'iga i le tasi so'oga e lagolago ai le fa'aogaina o le bandwidth maualuga ma le maualuga-density cabling system applications.E ogatasi ma le IEC 61754-7 ma le US TIA-604-5 Standard.I le taimi nei, o numera sili ona taatele o fiber o le 8, 12, 16, ma le 24. 32, 48, ma le 72 fiber numera e mafai foi i faʻaoga faʻatapulaʻa.

MTP® (Multi-Fiber Pull Off) uaea ua fa'apipi'iina i so'o MTP® i itu uma e lua.MTP® feso'ota'iga ose fa'ailoga fa'ailoga a le US Conec mo se fa'asologa o le so'oga MPO fa'atasi ai ma fa'amatalaga fa'alelei.O lea la, o feso'ota'iga MTP® e fa'amalie atoatoa i so'otaga uma MPO ma e mafai ona feso'ota'i sa'o ma isi mea fa'avae MPO.Ae ui i lea, o le MTP® fesoʻotaʻiga o se faʻaleleia atili o oloa faʻainisinia e faʻaleleia ai le faʻaogaina o masini ma faʻaogaina pe a faʻatusatusa i fesoʻotaʻiga MPO lautele.

MTP® vs MPO Cable: O a Eseesega?

O le eseesega autu i le va o le MTP® ma le MPO fiber optic cable o lo'o i totonu o latou feso'ota'iga.E pei o le fa'aleleia atili,MTP® uaeafa'apipi'iina i feso'ota'iga MTP® e sili atu ona lelei fa'ainisinia ma fa'atinoga fa'atino.

MTP® vs MPO: Fuafuaga faʻainisinia

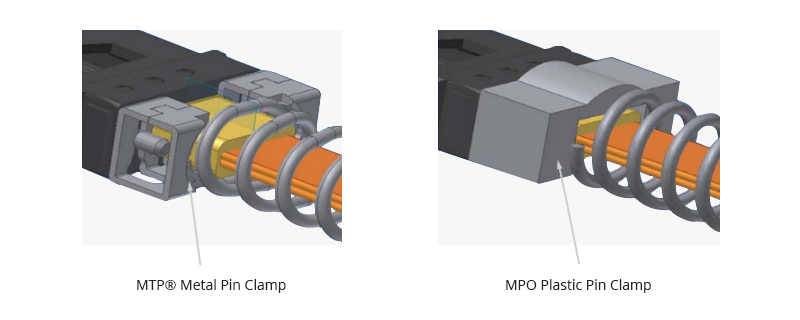

Fa'amau Fa'amau

O feso'ota'iga MPO e masani ona fa'apipi'iina i pine palasitika maualalo, lea e mafai ona ta'e ai pine fa'atasi ma le fa'asoso'o pea o le uaea, ae o le MTP® o lo'o i ai se pine u'amea e fa'amautinoa ai le malosi o le pipii i luga o pine ma fa'aitiitia ai so'o se gau fa'afuase'i pe a fa'aipoipoina so'o. .I le MTP® connector, o le oval spring e faʻaaogaina e faʻateleina ai le va i le va o le alava lipine ma le tautotogo, lea e mafai ona puipuia le alava lipine mai mea leaga i le taimi o le faʻaofiina.O le mamanu MTP® e aofia ai se pine fa'amau ma le oval spring o le a mautinoa ai le saogalemu o le nofoa puna, ma sili atu le kilia i le va o le puna ma le lipine uaea ina ia fa'aitiitia ai le lamatiaga o le faaleagaina o le uaea.

Ata 1: MTP® vs MPO Cable Pin Clamp

Ferrule Opeopea

O le ferrule opeopea o loʻo faʻaaogaina i se MTP® cable design mo le faʻaleleia o le faʻaogaina o masini.I se isi faaupuga, o le ferrule opeopea o le MTP® connector e mafai ona opeopea i totonu e fa'amautu ai le fa'afeso'ota'i fa'aletino i luga o se paga fa'aipoipo i lalo o se uta fa'atatau.Ae ui i lea, o le MPO connector e le o gaosia ma le ferrule opeopea.O le fa'aogaina o le fe'au fa'afefe na matua taua tele mo fa'aoga e fa'apipi'i sa'o ai le uaea i se masini Tx/Rx galue, ma o se tasi lea o mafua'aga autu na avea ai le MTP® ma feso'ota'iga o filifiliga mo fa'aulufalega optics Tx/Rx talosaga.

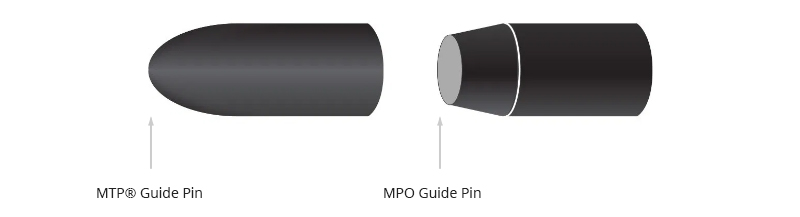

Fa'amau ta'iala

E le pei o feso'ota'iga alava tasi, o mea fa'apipi'i mo feso'ota'iga tele-fiber e mo na'o le fa'aogaga.O le mea lea e taua tele ai pine ta'iala mo le fa'aoga sa'o pe a fa'aluaina ferrules MT se lua.O pine ta'iala na fa'aogaina e MTP® ma MPO feso'ota'iga e 'ese'ese fo'i.O lo'o fa'aogaina e le MTP® so'otaga fa'apalepale uamea elliptical pine pine e fa'aitiitia ai le aofa'i o otaota e ono pa'u i pu o pine ta'iala po'o luga o le pito pito o le ferrule.Ae ui i lea, o pine taiala fa'apipi'i fa'aogaina e feso'ota'iga MPO o le a maua mai ai le tele o otaota pe a fa'aaoga.

Ata 2: MTP® vs MPO Cable Guide Pins

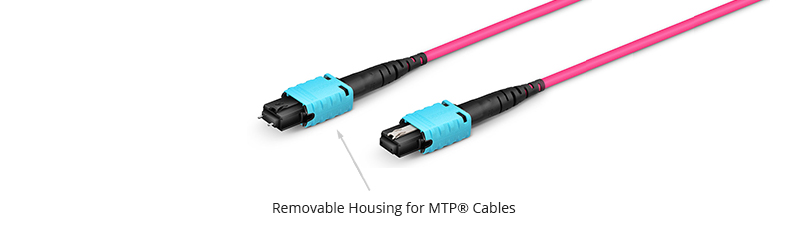

Fale Aveesea mo MTP® Uaea

A fa'atusatusa i le va o le MTP® vs MPO, o latou fale e mafai ona aveese o se tasi lea o mea taua.O le MTP® connector ua mamanuina ina ia i ai se fale e mafai ona aveese e mafai ai e tagata faʻaoga ona toe galue ma toe faʻaleleia le MT ferrule ma faigofie ona maua le avanoa i suʻega faʻatinoga ma ia suia malie le itupa pe a uma le faʻapotopotoga poʻo le fanua.O lo'o iai le MTP® cable e ta'ua o le MTP® PRO cable lea e mafai ona fa'ataga vave ma lelei le fa'apenaina o itupa ma polarity i totonu o le fanua a'o fa'amautinoa le sa'o ma le fa'atinoga o oloa.

Ata 3: MTP® Fale Aveesea Uaea

MTP® vs MPO: Fa'atinoga Fa'atino

Fa'aofi-toilalo

O le MPO connector ua aloaia o se tulaga faʻavaomalo i le fausaga fesoʻotaʻiga mo le tele o tausaga.O feso'ota'iga MTP®, e pei o le fa'asologa maualuga, ua fa'aleleia atili e fa'aitiitia ai fa'afitauli e pei o le gau, pa'u pepa, ma isi.MTP® connectors i MTP® cables ua mamanuina ina ia mautinoa le saʻo o le faʻaogaina o itu tane ma fafine, lea o le a fesoasoani e faʻaitiitia ai le faʻaofiina o le gau ma le toe faʻafoʻi mai le gau pe a faʻasalalau faʻamatalaga i le maualuga-density cabling systems.E lē gata i lea, o lo'o fa'aauau pea le fa'aleleia atili o fua faatatau o gau o fa'aofiina MTP®, o lea ua fa'atusalia fua fa'aletonu na va'aia e feso'ota'iga fibre ta'itasi i nai tausaga talu ai.

Fa'atuatuaina

Pe a faatusatusa i uaea MPO talu ai, o le MTP® cable formats e mafai ona faʻapipiʻi i totonu e aunoa ma ni faʻafitauli, lea e itiiti se faʻalavelave faʻafuaseʻi e ono mafua ai le le mautonu.O vaega o feso'ota'iga i totonu na toe fa'avasegaina i le MTP® fa'atulagaina ina ia mautinoa le fa'atotonugalemu lelei o malosi masani i le va o ferrules fa'aipoipo, fa'amautinoa le fa'afeso'ota'i fa'aletino uma fa'alava fa'aiila pito i totonu o le ferrule.E le gata i lea, o le taʻitaʻia i luga o pine faʻataʻitaʻiga saʻo i se foliga elliptical ua faʻamalosia foi, faʻaitiitia ai le ofuina ma loimata ma otaota mai le faʻapipiʻiina ma toe faʻapipiʻi le fesoʻotaʻiga i le tele o taimi.O nei fa'aopoopoga fa'aopoopo i le sa'o o vaega fa'afeso'ota'i MTP® na fa'atupuina ai le fa'atuputeleina o le mautu ma fa'ateleina le fa'atinoina o le tumau a'o fa'aauau pea le fa'aleleia atili o le fa'atuatuaina o feso'ota'iga.

Fua'iga i le lumana'i o MTP® Uaea

Faatasi ai ma le 20-faaopoopo-tausaga talaʻaga o le faʻaleleia e le gata ma le isi augatupulaga o le alualu i luma o le a oʻo mai, o fesoʻotaʻiga MTP® na faʻatagaina fesoʻotaʻiga tele-fiber e maua ai le faʻatinoga sili atu, faʻalagolago.I le avea ai o se fofo sili ona lelei ua fuafuaina mo le tulaga o le televave, maualuga, ma le faʻatulagaina lelei, o le MTP® fesoʻotaʻiga fua faʻatatau i talosaga tutusa fou e pei ole 400G Ethernet e mafai ona tamomoe i luga ole 32, 16, ma 8 fibers.Faatasi ai ma inisinia malosi, MTP® fesoʻotaʻiga ua faʻaaogaina lautele i le tele o siosiomaga faʻaogaina, e aofia ai i latou e maualuga le susu, vevela tele ma le malulu, ma fesuiaiga o le vevela.

O uaea MTP® e maua ai fo'i le taua tele mo le tele o feso'ota'iga tekonolosi, lea e le na'o le fausiaina mo le mega-cloud, fa'amatalaga tetele, ma le fa'atuputeleina o komepiuta.O fa'afou fou o feso'ota'iga MTP® ua mamanuina e galulue e le gata i feso'ota'iga fiber-to-fiber ae fa'atasi ai ma isi tekonolosi i le tele o alamanuia tūsa'o e aofia ai mea tau tupe, foma'i, a'oa'oga, colocation, ma isi.

Taimi meli: Nov-13-2021